Mesh belt conveyor chain's effect

Mesh belt conveyor: modular mesh belt uses plastic hinge pins extending over the entire width of the conveyor belt to assemble the injection moulding mesh belt into interlocking units. This method increases the strength of the conveyor belt and it can be cut and connected into any width and length required. The baffle and side plate can also be interlocked with hinge pins and become one of the integral components of the conveyor belt.

The material of the conveyor belt of the mesh belt conveyor includes carbon steel, stainless steel and thermoplastic chain. According to the needs of your products, it can choose chain plate of different width and different shapes to complete the plane conveying, plane turning, lifting, descending and other requirements.

The structural style of the mesh belt conveyor includes horizontal linear conveyor, lifting and climbing conveyor, etc. The conveyor belt can be added with lifting baffle and side baffle.

Classification of mesh belt conveyors

Plastic steel mesh belt conveyor:

It is a supplement to the traditional belt conveyor, it overcomes the belt conveyor maintenance difficulties, scallops easily torn, punctured, the shortcomings of corrosion, to provide a safe, efficient, simple maintenance transmission mode. Because the mesh belt conveyor uses modular mesh belt and sprocket drive is adopted in transmission mode, the conveyor mesh belt is not easy to snake and run away, the belt is thick and can withstand cutting, and it has characteristics of collision, oil and water resistance and other characteristics, so that its application in various industries will not cause troubles in maintenance, especially in the replacement of convey belt, the costs can be reduced for plastic steel mesh belt conveyor. Different mesh belts of different materials can play different conveying roles and meet the needs of different environments. Through the modification of plastic materials, the conveyor belts can meet the conveying requirements of ambient temperature between -10 degrees Celsius and 120 degrees Celsius. The pitch of mesh belts is 12.7, 19.05, 25.4, 27.2, 38.1, 50.8, and the aperture ratio is 2% to 48%.

Usage: It is used widely in the transportation of beverage bottles, aluminium cans, pharmaceuticals, cosmetics, food and other industries. By choosing different mesh belts, it can be made into special equipment for bottle storage stand, hoister, sterilizer, vegetable cleaner, cold bottle machine and meat food transportation and other industries. Others: Considering the sustain tension limitation of the mesh belt, the longest single line length does not exceed 20 meters generally.

Modular mesh belt conveyor: modular mesh belt uses plastic hinge pins extending over the entire width of the conveyor belt to assemble the injection moulding mesh belt into interlocking units. This method increases the strength of the conveyor belt and it can be cut and connected into any width and length required. The baffle and side plate can also be interlocked with hinge pins and become one of the integral components of the conveyor belt.

The material of conveyor belt includes: PP (polypropylene), PE (polyethylene), ACETAL (acetal), NYLON (nylon).

The structural style of the mesh belt conveyor includes horizontal linear conveyor, lifting and climbing conveyor, etc. The conveyor belt can be added with lifting baffle and side baffle.

Chinese

Chinese English

English

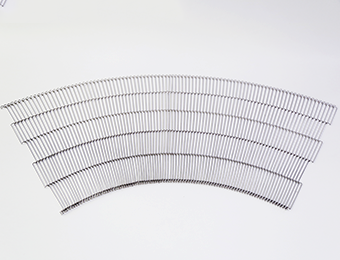

Spiral conveyor belt

Spiral conveyor belt