Rubbed problem of stainless steel chain in work

The industrial chain of stainless steel chain plate has been used widely in the mesh belt industry, and the problems occured in its operation has always been a headache for our technicians, the most common of which is the friction problem. For this reason, the company has also done a lot of research work. Today, small editor shares with you the solution to the friction problem in the operation of stainless steel chain plate.

Recently, after another comprehensive discussion and research, the technicians of the company used a variety of friction-reduction materials, lubricants, greases, solid lubricants to reduce friction and wear between the stainless steel chains, When choosing the lubricant chain of transmission, the first consideration is the structure style, the suitable ambient temperature and the specification of lubricant chain. Lubricating oil of mechanical oil of gb443 64 can be used in stainless steel chain. The chain must be permeated with anti-rust lubricating oil. In the factory, in order to prevent the loss of dripping oil during the storage and transportation, the thickening agent of lubricating oil is often added. Generally, each manufacturer prepares the thickening agent by itself. The author uses a compromise scheme for its anti-rust and lubrication performance.

Stainless steel chain plate is one of the most familiar and common structural steel, so what brings stainless steel chain plate with strong anti-corrosion performance? According to experts, the corrosion resistance of stainless steel chain plate depends on the chromium of oxidation resistance mentioned above. However, when the chromium content is higher, the corrosion resistance of stainless steel chain plate can still be improved, but it is not obvious. The reason is that the type of surface oxides is changed to the equivalent of that formed on simple chromium metal when chromium is used to alloying steel. This tightly adhered chromium-rich oxide protects the surface from further oxidation.

Chinese

Chinese English

English

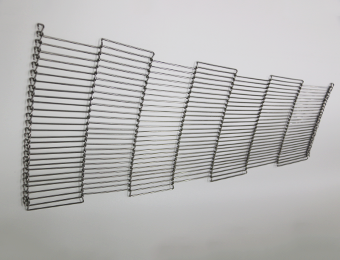

Spiral conveyor belt

Spiral conveyor belt